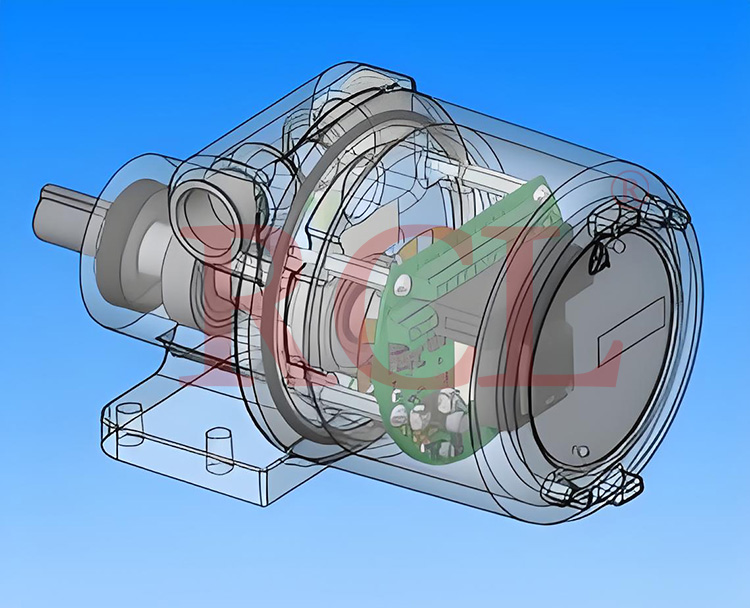

In modern industrial automation and intelligent equipment, rotary encoders play a vital role as "eyes". It accurately tells the equipment "how many turns" and "where it is", ensuring the flexible movement of the robot arm, the precise processing of the CNC machine tools, and the smooth operation of the servo motor. Inside the encoder, there is a "heart" that silently supports its stable work - that is the bearing.

As Ningbo Shilong Bearing Co., Ltd. (brand name RCL), we are well aware of the special requirements of encoders for bearings: they must be small to fit in limited space, and strong and durable to cope with various challenges. Our 67/68 series thin-walled bearings are born to meet these demanding requirements.

1. Why do encoders prefer thin-walled bearings?

Imagine the inside of the encoder: circuit boards, optoelectronic components and other precision components are crowded together, leaving very limited space for bearings. At the same time, encoders are often installed on high-speed motors. Withstand the force brought by belt pulling or gear meshing. Face harsh environments such as factory oil, humid water vapor, and even mine dust.

Ordinary bearings are large and heavy, making them difficult to handle. The "thin-wall" design of the RCL 67/68 series thin-wall bearings is the solution: it saves more space. With the same aperture, it is made thinner, freeing up valuable space for other key components inside the encoder. Designed for challenges, it is optimized specifically for the impact, vibration and complex environments commonly seen in encoders.

2. Advantages and highlights of the RCL 67/68 series thin-wall bearings

1. Stable rotation and accurate signal

Using special materials and precision design, it rotates very smoothly with very little friction. This allows the encoder to stably send out accurate position signals even at high speeds, without "losing rotation" or "misreporting positions".

2. Strong and durable, not afraid of vibration

The bearing itself has been reinforced and is particularly resistant to impact and vibration. Whether it is the strong vibration of mining equipment or the common bumps in factories, it can be stable and protect the internal precision components from damage. The sealing design also allows it to effectively resist the intrusion of dust, water vapor and oil.

3. Durable, worry-free and labor-saving

High-quality raw materials and rust-proof technology are used to resist corrosion such as moisture, weak acids and weak alkalis, and extend the service life in harsh environments.

The overall structure is reliable and has a long service life, which reduces the frequency of equipment maintenance and replacement.

4. Lightweight and flexible, easy to install

Lighter weight reduces the burden on high-speed rotating parts.

A variety of sizes are available, which can easily match the mainstream encoder models on the market and facilitate integrated installation.

3. Where can RCL thin-walled bearings show their skills?

The "precision brain" in the factory: At the core of CNC machine tools and machining centers, our bearings support the encoder to ensure that every cut is accurate.

"Iron Man" joints: At the joints of the industrial robot arm, the encoder relies on small and reliable thin-walled bearings to achieve flexible and precise motion control.

The "heartbeat monitor" of the motor: Inside the servo motor, the bearing ensures that the encoder feedbacks the motor speed and position in real time, allowing the motor to run smoothly and efficiently.

"Sentinels" in challenging environments: In the humid environment of textile mills, the oily environment of automated production lines, and even the strong vibration environment of mining machinery, RCL bearings can protect the normal operation of encoders.

4. Choose RCL, choose a reliable partner

Ningbo Shilong Bearing (RCL) focuses on the research and development and manufacturing of precision bearings. For the 67/68 series thin-walled bearings, we promise:

Quality first: strict production processes and quality control to ensure that every bearing meets high standards.

Reliable performance: The products are fully tested and strive to provide stable and reliable support in encoder applications.

Service support: We are happy to communicate with customers and provide suitable solutions and support.

In the era of automation that pursues higher precision and higher efficiency, the stability of encoders is the cornerstone. RCL 67/68 series thin-walled bearings, with its compact body, excellent reliability and long-term durability, have become the core components of many high-end encoders that are worthy of trust. Although it is not conspicuous, it silently carries the heavy responsibility, ensures the precise operation of equipment, and contributes solid strength to industrial intelligence.

Choose RCL to inject a reliable power into your encoder!